Repair of two cement mill gear units at a Belgian cement plant

1 Introduction

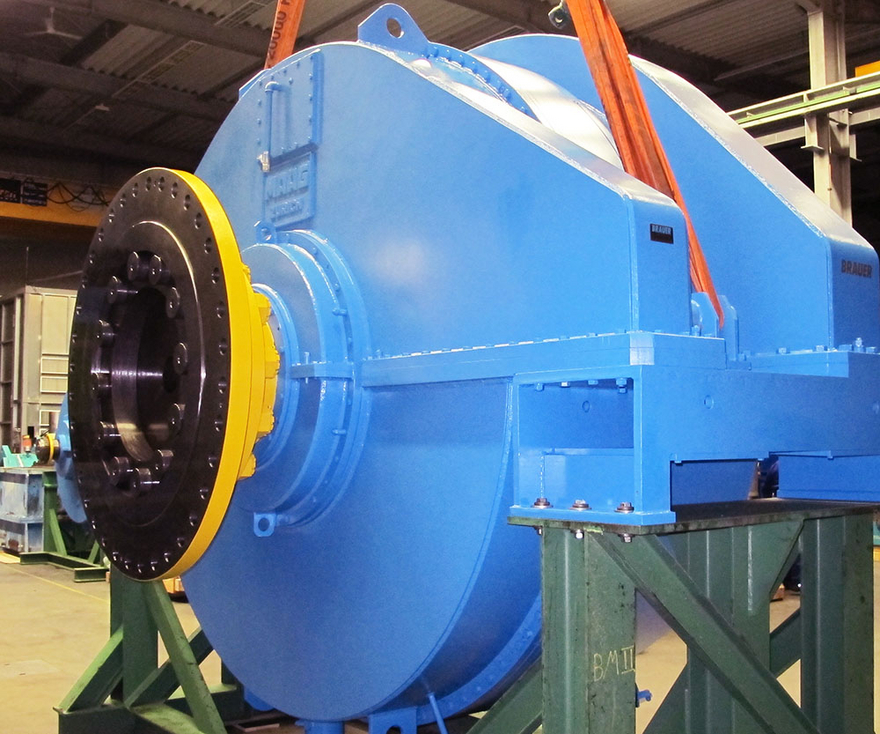

Numerous cement plants can boast of drivetrains with mechanical gearing that have been in service for decades. In many cases, a general overhaul would be desirable, but the prolonged downtime, or perhaps the lack of a good extraction option, makes it appear unfeasible. Consequently, repairs are often limited to in-situ mending and patching in order to fix acute damage and keep production going. Obviously, high quality is not always achievable, and the operational reliability of the entire drivetrain usually remains more or less limited. Frequently, though, the only way to ensure proper operation with no unexpected outages is to perform a full-scale overhaul. A cement plant in Antoing, Belgium, has a pair of horizontal ball mills with two-stage planetary gear units (Fig. 1) that have been in service for about 50 years. Some time ago, one of the machine’s smaller stages was repaired, and a subsequent video endoscopic inspection performed by Brauer Maschinentechnik AG revealed some damaged teeth and cracks in the casing.

It would not have been possible to pull the 47-ton gear units with the hall’s 10-ton crane. In addition, the machine hall had no opening large enough to enable loading of the gear units. The customer therefore called in Brauer Maschinentechnik AG to help work out a plan for performing a general overhaul during the four-week wintertime production pause.

Challenges

For Brauer Maschinentechnik AG, the repair of large gear units is a core business activity. At the Antoing plant, however, there were a number of challenges to be mastered. All of the following work had to be completed within the short, four-week span of the production pause:

» removal from the plant

» transfer to the Brauer plant in Bocholt

» complete disassembly of both gear units

» cleaning

» damage assessment

» reassembly of both gear units with new teeth and bearings

» return to plant and reinstallation

» recommissioning

In-situ repair was not possible within the time available, because the gearing’s configuration was such that the gears could only be worked on consecutively. That would have necessitated a lot of complicated rigging. Moreover, it would have been extremely difficult to reassemble plain-bearing gear units in an environment as dusty as a cement plant. There was no available means of pulling or lifting the gear units out of the hall. Since there are other storeys situated above and below the machine hall, removing the roof was no option, either. In addition, the ceiling height of the hall is very low for any lifting equipment to provide enough height for hoisting the gear units off their foundations. The fact also had to be considered that the bottoms of the gear units extend well below the top of the foundations in the installed state.

Preliminary considerations and preparations

Since in-situ repair was out of the question, some way of extracting the gear units from the machine hall had to be found. After weighing the options, it was decided to remove part of the exterior wall and install appropriate lifting and traversing equipment. While it was relatively easy to open up the exterior wall, the preparations for raising and extracting the gear units was substantially more involved. After the customer checked the building’s statics, steel girders were installed one floor down to help support the floor of the machine hall.

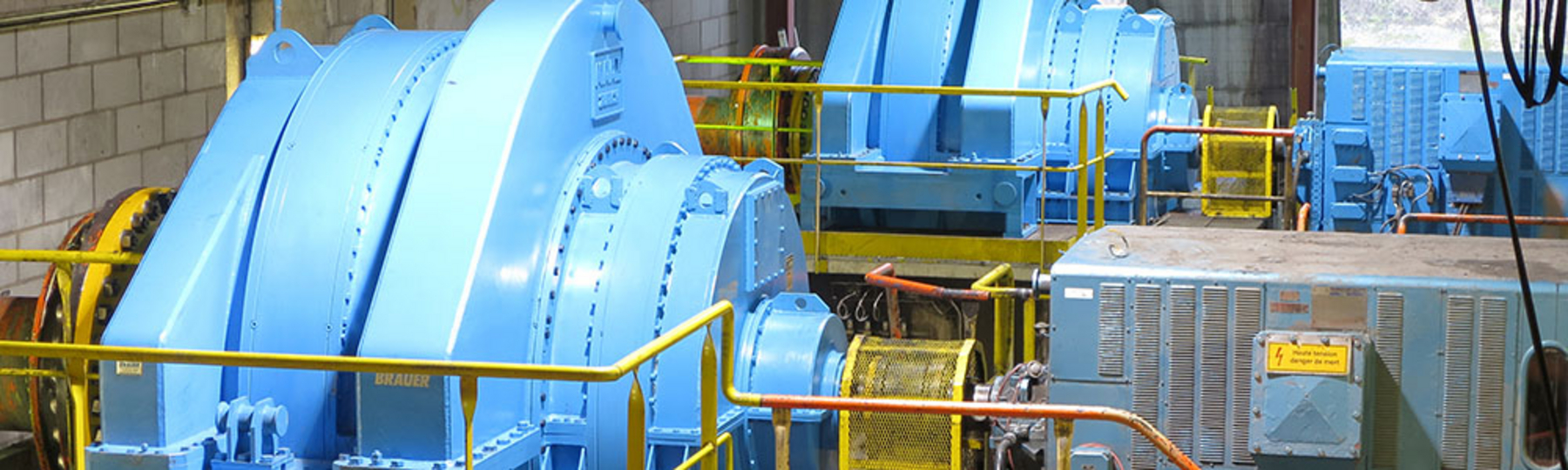

A special, demountable steel framework was installed to enable use of the hall crane, i.e., to extract and load the gearing within the confines of the machine hall. With the hall’s maximum permissible static load limited to 40 t, it was not possible to extract the entire 47-t gear units all in one piece. Brauer Maschinentechnik AG performed computer-based simulations of partial disassembly in stages, in-place disassembly of the drivetrains and lifting of the remainder off the foundations. Then a suitable set of transport cradles was prepared. Spare parts with long lead times (ring gears and the like) had to be manufactured in advance, so they would be available on time for the overhaul. Once the commencement date of the wintertime production pause was set, a team of well-equipped specialists was scheduled for the on-site disassembly and reassembly work, the requisite capacity reserved for the repair in the workshop, and appropriate arrangements made for transports requiring special permits. With all these preparations in place, the actual overhaul of the gear units at Brauer Maschinentechnik AG in Bocholt was implemented within a short span of time.

Conduct and repair

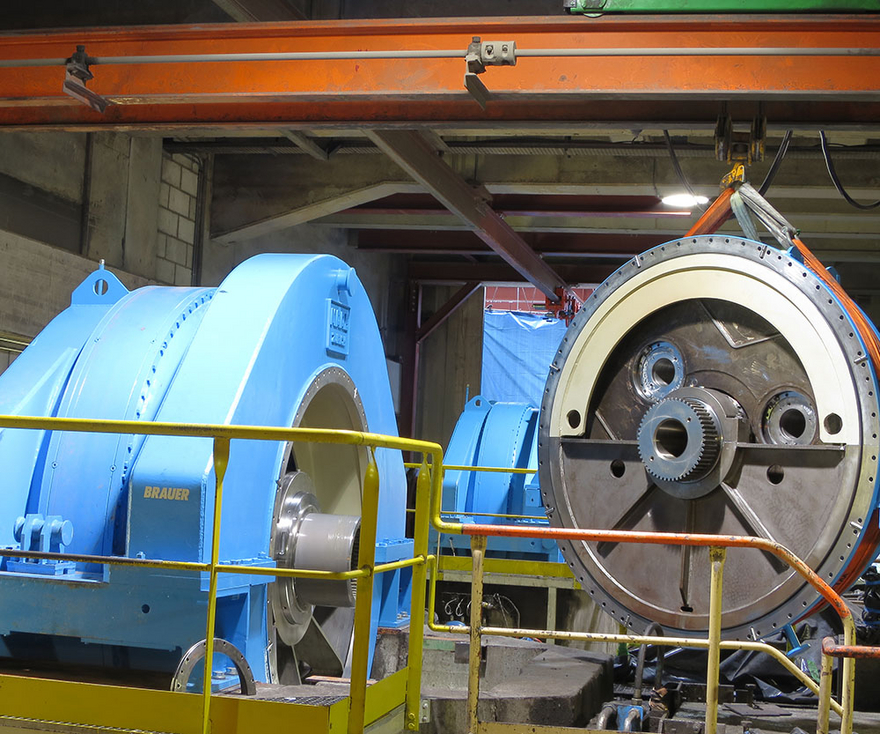

Disassembly of the mills’ planetary gear units had to be executed according to an exact, predetermined order of sequence. First, the field-service technicians disassembled the two relatively small (9-ton) planetary stages, extracted them from the gearboxes and off the foundations with the aid of the 10-ton hall crane, deposited them on the transport cradles and prepared them for transport. After the heavy curved-tooth couplings to the cement mill were separated and secured came the much more difficult part: disassembly of the big planetary stages, each weighing 38 tons in total. A steel framework with pull-out rails was installed over the existing foundations to enable lifting and suspension of the large stages. In addition, a steel boom was installed for depositing the components on the transport cradles and readying them for transport (Fig. 2). With deference to the very tight schedule, transport to Brauer Maschinentechnik AG in Bocholt took place at night. In order to accelerate the repair work as far as possible, the two large and two small stages were assigned to four different teams on arrival at the Bocholt facility.

Hence, all components were completely disassembled and inspected in parallel operations. Damaged teeth, bearings and other component parts were either replaced or appropriately reconditioned. Casing cracks were repair-welded, and an annular-toothed ring gear with a diameter of more than 3 m was bored out to fit the existing gearbox (Fig. 3). The overhaul included a complete dimensional survey of all parts for spare-part supply purposes. Nighttime transport enabled punctual return of the parts to the job site, which the local field service team had already prepared for the reassembly phase. A duty-ready truck-mounted crane was used for unloading all components and immediately reinserting them in the opposite order (Fig. 4), including final fine alignment of the gearing and motors by specialists from Brauer Maschinentechnik AG (Fig. 5). Just before the drivetrains were returned to service, their lubrication systems were cleaned and optimized. Finally, the motors and intermediate shafts up to the mills were connected for starting and a check of the oil pressures. Both drivetrains were cleared for production operations right on schedule.

Goal achieved

Nine month later, Brauer Maschinentechnik AG performed a video endoscopic inspection that documented, as expected, the gear units’ good condition and fitness for unrestricted operation.

*Thorsten Pasz died unexpectedly on 23.07.2019.